DSR Digital

English Name:Digital Speed Rotator

Model:DSR

Origin:China

Manufacturer:Wuhan DC New Energies Co., Ltd

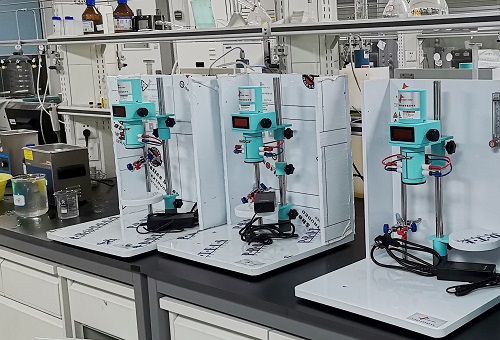

DSR rotator

Technical Parameter

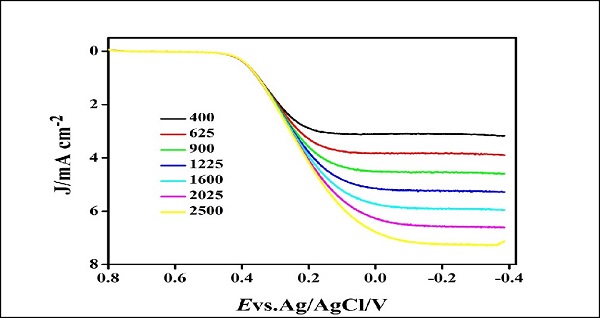

· Rotation rate:0 to 10,000 RPM; Motor Power:20W

· Brush:Silver carbon brush contact connection, excellent anti-interference performance.

· Digital chip, precise speed. DC power supply, which reduces the interference of power grid on the host, and has strong anti-interference ability.

· Signal input interface, which can control the speed by inputting external signals (from the potentiostat);

· Explosion proof: The latest explosion-proof design ensures personal and equipment safety

· Shaft:Total length 170mm,OD 15mm,stainless steel rod with PEEK shroud,internal threads. This shaft is compatible with the DSR rotator, and accepts E5, E6, and E7 Series rotating disk (RDE) and rotating ring-disk (RRDE) electrode tips.

· Glassy Carbon Ring-disc Electrode(RDE) Tip: 5.0 mm disk OD, 15.0 mm OD PTFE shroud. Disk: glass carbon, Shroud: Teflon, PTF; Operating temperature: room temperature.External thread design.

· Rotating Ring-disc Electrode Tip(RRDE): Glassy Carbon Disk, Platinum Ring;15.0 mm OD PTFE shroud.

· Disk OD 5.61 mm, Ring OD 7.92 mm, Ring ID 6.25 mm, tolerance 0.01mm; Ring-Disk Gap = 320 μm.

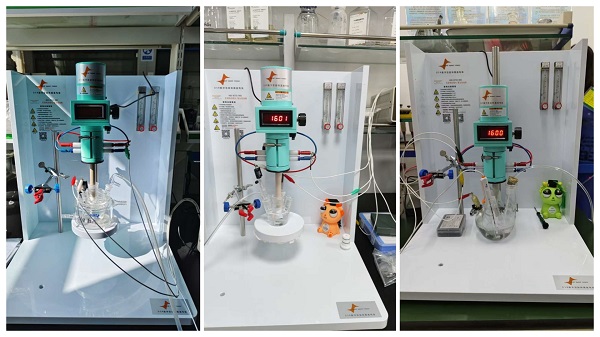

· Collection Efficiency :37%Electrochemical Cell: Standard 125 mL cell features five round glass ports; Customization is acceptable.

· Gas flow meter: Two flow meters, 1pc of inert gas flow meter and 1pc of oxygen flow meter. The inert gas flow meter is used to regulate the blowing of inert gas into the electrochemical Cell; The oxygen flowmeter is used to regulate the oxygen flow into the electrolyte for oxygen saturation.

· After sales service: one-year warranty, lifetime maintenance, free training and application support services provided.

Typical Applications of DSR Rotator

DSR rotator is used in combination with electrodes and potentiometers to meet diverse research and experimental needs, and is suitable for:

Research and Evaluation of Hydrogen Fuel Cell Catalysts

Research on Lithium Air Battery

Electrochemical Dynamics Study

Research on Oxygen Reduction Reaction (ORR)

Research on Oxygen Evolution Reaction (OER)

Research on Hydrogen Evolution Reaction (HER)

Research on Carbon Dioxide Reduction Reaction (CO2RR)

Evaluation and Research of Corrosion Inhibitors

Research on Corrosion Potential of Metal Materials, etc

Phychemi(HK)company has been deeply involved in fuel cell research for nearly 20 years, covering testing schemes from pre-treatment, catalyst to membrane electrode. We also provide customers with a complete set of solutions for electrocatalysis and CO2 reduction.

Based on the characteristics of electrochemical experiments, it is important to have good pre-treatment equipments. In response to the needs of our customers, our company provides a complete set of pre-treatment equipment for fuel cell testing, including Ink Dispersers (especially suitable for non precious catalyst research), Rotating Electrode Polisher, Electrode Spin Coater, etc.

Our Customer Cases