DSR-M

Modulated Speed Rotator

Model:DSR-M

Origin:China

Manufacturer:Wuhan DC New Energies Co ., Ltd

Technical Parameter of DSR-M rotator

· Adjustable range from 0 to 10,000 RPM;

Rate Accuracy: 100 to 200 RPM: Accurate to within ±2 counts of display reading

200 to 10,000 RPM: Accurate to within ±1% of display reading

· Motor Power:20W

· Silver-carbon brush contacts;

· Output signal ratio: 1 RPM/mV (±1%)

· Brush:silver-carbon brushes, excellent anti-interference performance, minimal contact resistance, can effectively reduce current acquisition errors, and has a long service life.

· Explosion proof: The latest explosion-proof design ensures personal and equipment safety.

· Shaft:Total length 170mm,OD 15mm,stainless steel rod with PEEK shroud,internal threads. This shaft is compatible with the DSR-M rotator,

· Speed control: The speed can be manually adjusted infinitely, or it can also be automatically controlled directly through the cable matched with the potentiostat.

· Glassy Carbon Ring-disc Electrode(RDE) Tip: 5.0 mm disk OD, 15.0 mm OD PTFE shroud. Disk: glass carbon, Shroud: Teflon, PTF; Operating temperature: room temperature.External thread design.

· Rotating Ring-disc Electrode Tip(RRDE): Glassy Carbon Disk, Platinum Ring;15.0 mm OD PTFE shroud.

· Disk OD 5.61 mm, Ring OD 7.92 mm, Ring ID 6.25 mm, tolerance 0.01mm; Ring-Disk Gap = 320 μm.

· Collection Efficiency :37%

Main characteristics of DSR-M

The speed of DSR-M rotator is displayed by LED, which can be adjusted through the knob below the LED, with a range of 0 to 10850 RPM.

There is a voltage signal output interface on the back panel of the DSR-M rotator, which can be connected to an external voltmeter or data acquisition system to display changes in voltage signals. The speed can also be adjusted using an external signal source through the interface on the panel if needed. External signal sources can be sine waves, square waves, and other waveforms.

The external acceleration characteristics of the DSR-M rotator enable its rotational speed to change synchronously with the external waveform. This feature is particularly suitable for applications in hydrodynamic regulation.

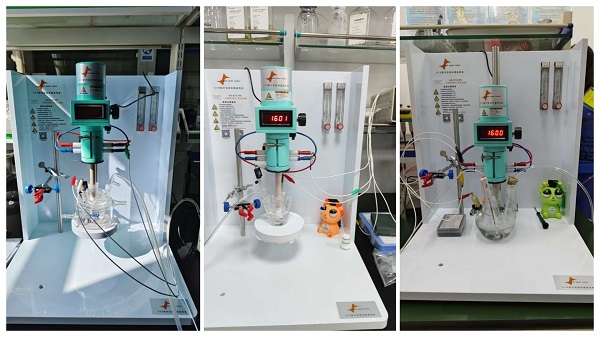

The DSR-Mrotator is easy to install and remove, and takes up little space. it can be easily moved up and down and connected to the cell for electrode immersion or removal experiments.

The support frame of the DSR-M rotator is fabricated from chemically resistant polypropylene material. It can be placed in a glove box conveniently for conducting research on non-aqueous systems.

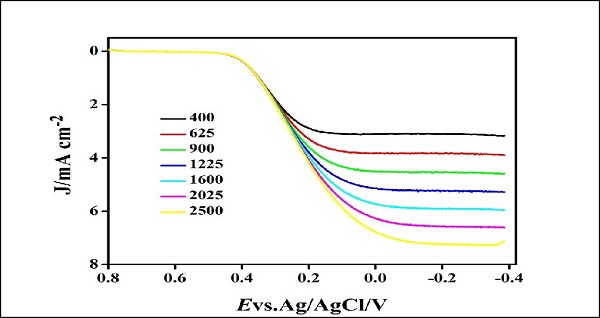

Typical Applications of DSR-M Rotator

DSR-M rotator is used in combination with electrodes and potentiometers to meet diverse research and experimental needs, and is suitable for:

Research and Evaluation of Hydrogen Fuel Cell Catalysts

Research on Lithium Air Battery

Electrochemical Dynamics Study

Research on Oxygen Reduction Reaction (ORR)

Research on Oxygen Evolution Reaction (OER)

Research on Hydrogen Evolution Reaction (HER)

Research on Carbon Dioxide Reduction Reaction (CO2RR)

Evaluation and Research of Corrosion Inhibitors

Research on Corrosion Potential of Metal Materials, etc

Phychemi(HK)company has been deeply involved in fuel cell research for nearly 20 years, covering testing schemes from pre-treatment, catalyst to membrane electrode. We also provide customers with a complete set of solutions for electrocatalysis and CO2 reduction.

Based on the characteristics of electrochemical experiments, it is important to have good pre-treatment equipments. In response to the needs of our customers, our company provides a complete set of pre-treatment equipment for fuel cell testing, including Ink Dispersers (especially suitable for non precious catalyst research), Rotating Electrode Polisher, Electrode Spin Coater, etc.

Our Cutomer Cases